EPA Licensed Operations

Collection and handling aligned with NSW regulatory requirements.

Reliable bulk tyre pickup and responsible recycling for tyre shops, dealers, and warehouse operations across New South Wales. EPA-aligned collection cycles designed to keep your site compliant while diverting waste tyres from landfill.

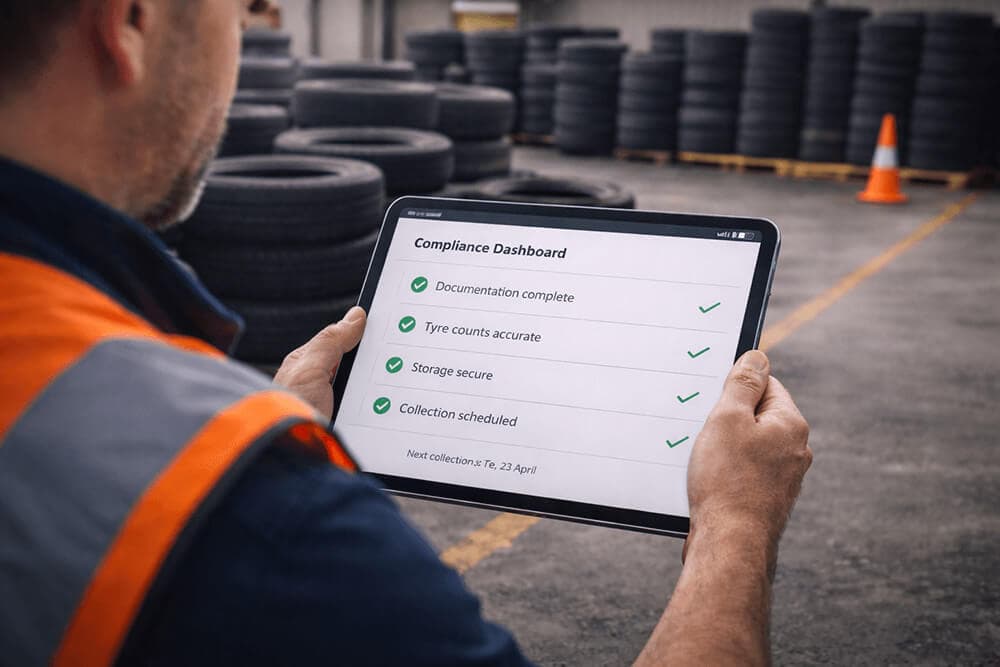

Operational Confidence

ATR combines compliance, documentation, and service reliability so businesses can run cleaner tyre operations with less risk.

Collection and handling aligned with NSW regulatory requirements.

Load-level tracking and records to support cleaner audits and reporting.

Collection plans built for tyre shops, dealers, and warehouse volumes.

Predictable pickup cycles designed to reduce yard buildup and disruption.

ATR provides dependable commercial tyre collection and recycling services for businesses throughout NSW's major hubs.

Daily commercial tyre collection across Greater Sydney, from Homebush to the CBD and outer suburbs.

Reliable tyre recycling and pickup services for dealerships and workshops across the Newcastle region.

Scheduled commercial tyre disposal solutions for service centres and shops in Wollongong and surrounding areas.

Full documentation on every collection. We keep your records compliant and organised.

Consistent scheduled pickups you can count on.

We handle scheduling and collection logistics so your team can stay focused on operations.

Tyre shops, dealers, and service centres across NSW trust ATR to keep old tyres out of landfill. Whether you're a Bridgestone, Goodyear, or independent workshop, we make tyre disposal simple.

Our team schedules regular pickups from your location, collects used tyres, and ensures they are shredded and recycled through compliant pathways.

A simple, reliable process for commercial tyre collection and recycling.

Our team schedules regular pickups from tyre shops and dealerships. We handle passenger, 4x4, and commercial tyres across NSW.

Collected tyres are processed at our facility using mechanical shredding systems to support responsible material recovery.

Consistent collection and processing reduces stockpiling risk and supports cleaner tyre operations across your sites.

Field-informed guidance on tyre collection, compliance, and sustainability across New South Wales.

Understand how compliant tyre disposal reduces environmental risk, avoids penalties, and keeps your operations audit-ready.

Read article

Compare tyre recycling and landfill impact for NSW businesses, plus practical compliance and scheduling steps for cleaner operations.

Read article

A concise readiness checklist to support safer yards and faster, cleaner pickup operations.

Read articleAnswers to common questions about tyre collection and recycling services.